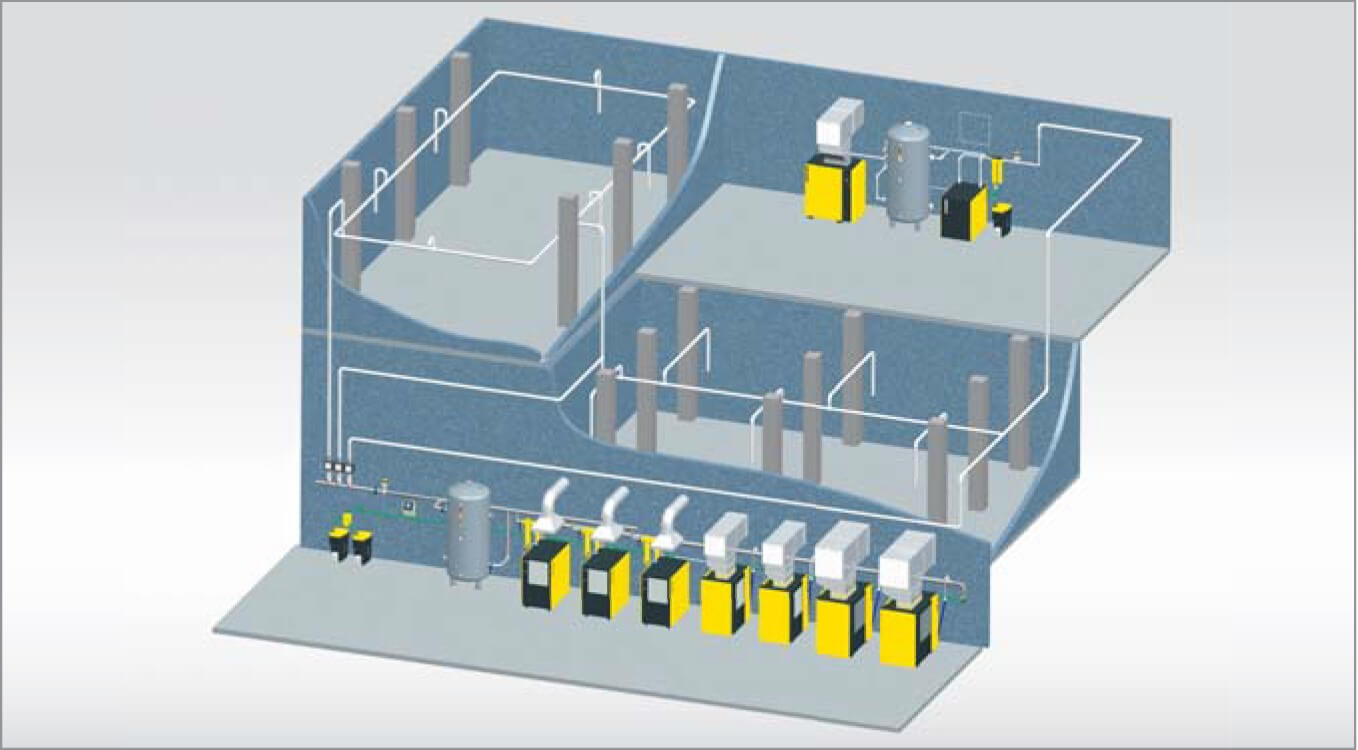

There are essentially three ways to distribute compressed air from the compressor system to the point of use: via branch line, ring main or distribution network.

As to which system is most suitable depends on the company concerned. When looking at efficient use of compressed air, it is important not only to focus on energy-saving air production, but to also consider the most effective method of air distribution.

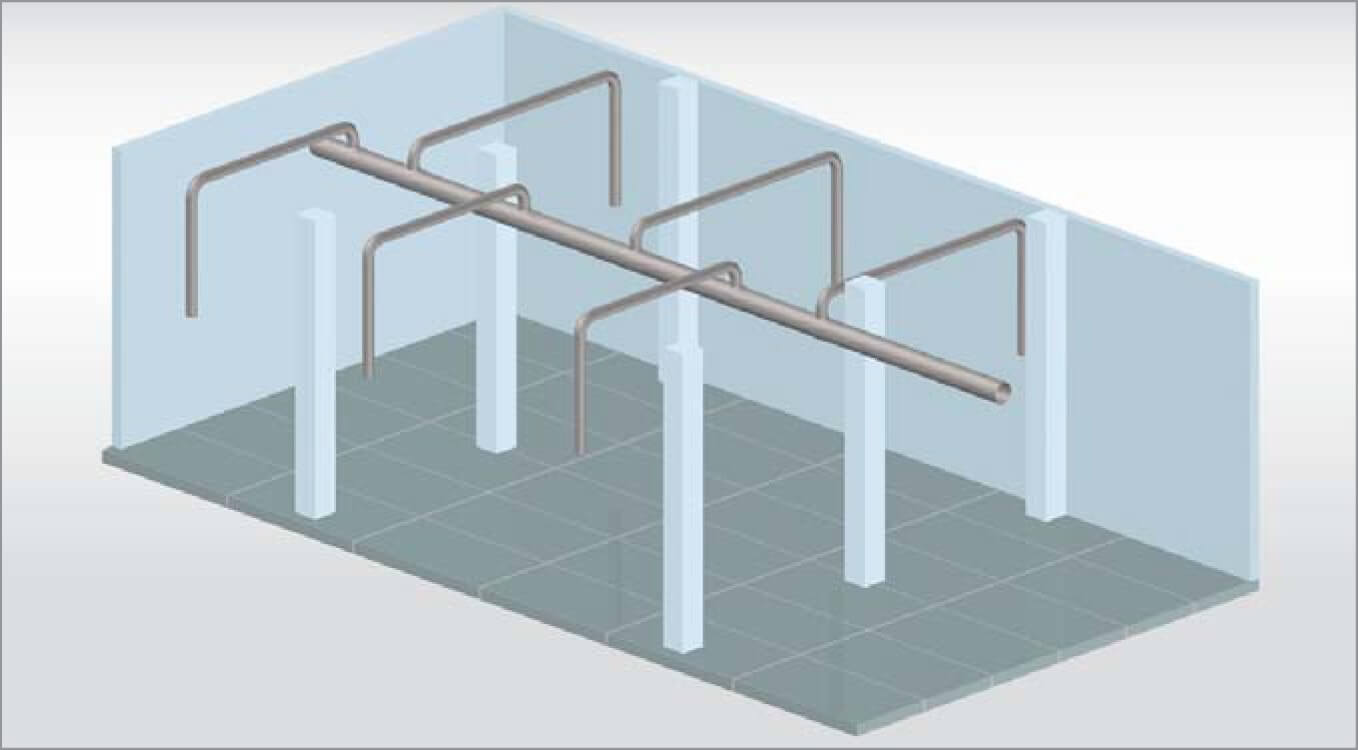

Branch line

Installation of a branch line with various outflow connections that lead to the individual air consumers (fig. 1) is relatively straightforward. The length of piping required for the branch line is comparatively short, but must have sufficient capacity to meet the system’s entire compressed air demand.

This means that the pipe diameter has to be significantly larger in comparison to ring main or distribution network piping. The connection lines to the air consumers also have to be larger, due to the increased distance from the main compressed air supply.

In addition, this solution does not allow individual sections of the system to be shut-down in order to facilitate system expansion or cleaning work for example. Branch line systems are therefore best suited to small businesses.

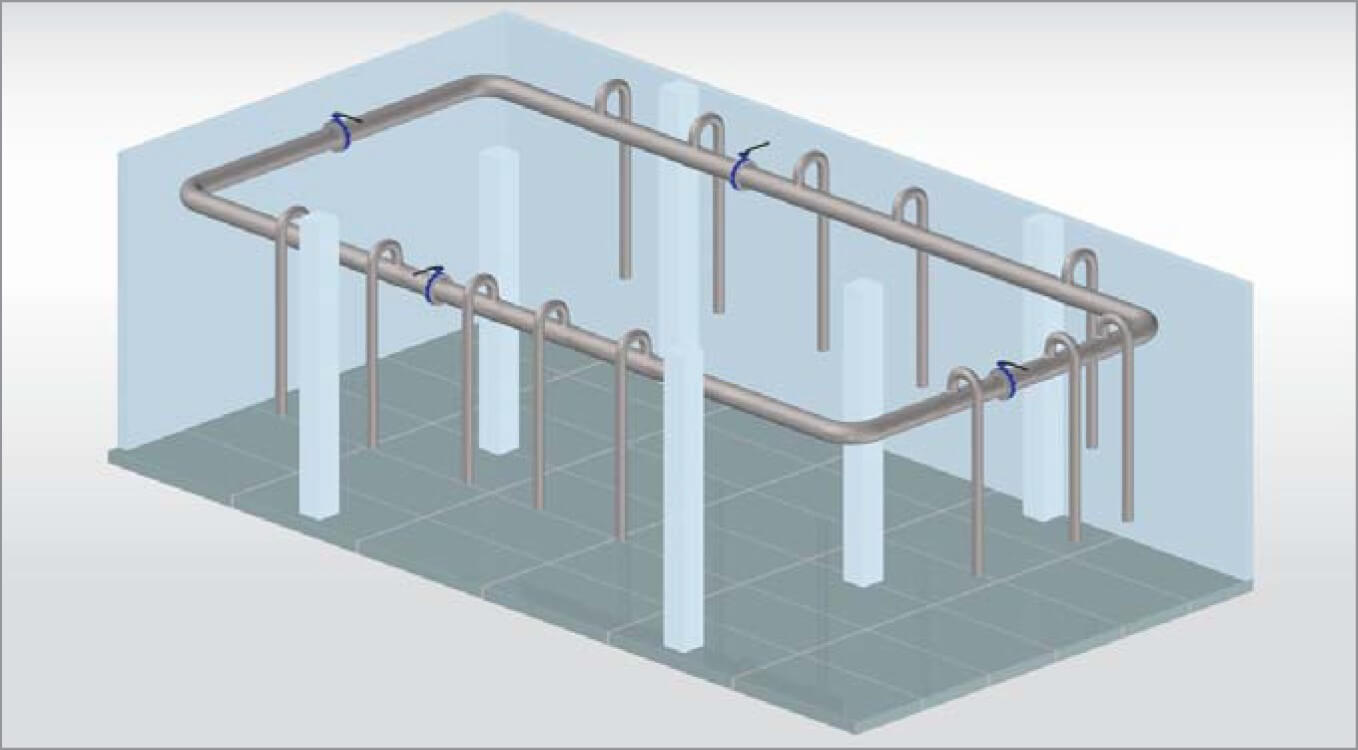

Ring main

Installation of a ring main (fig. 2) is more complex but has one considerable advantage over a branch line system: if using consumers each with the same compressed air demand, the connection pipe length and volume can be reduced by half. As a result, smaller diameter piping can be used and the capacity remains the same.

The connection lines are very short and are seldom installed any larger than DN 25 DN 25. Sufficient numbers of shut-off units should also be included in the ring main design, as this allows certain sections of piping to be taken out of operation for cleaning and system expansion purposes, leaving the rest of the air installation to operate as normal.

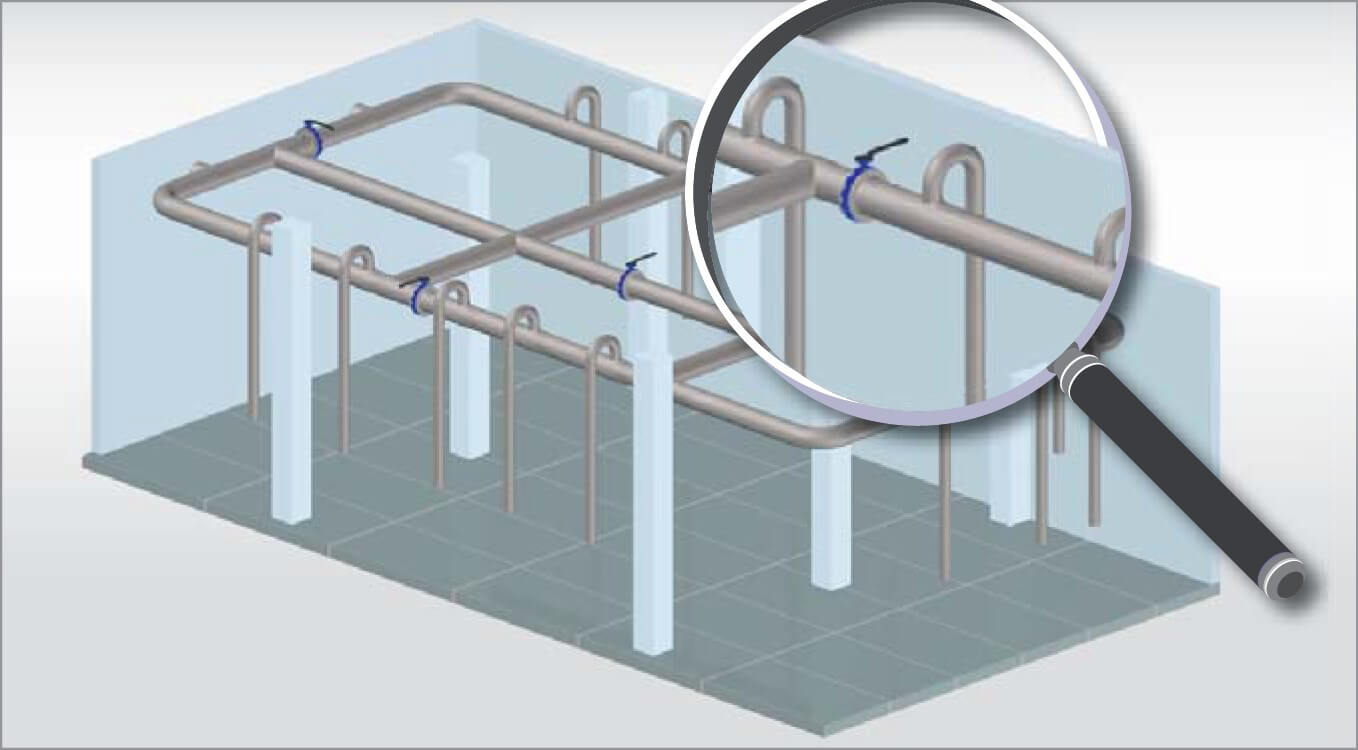

Compressed air distribution network

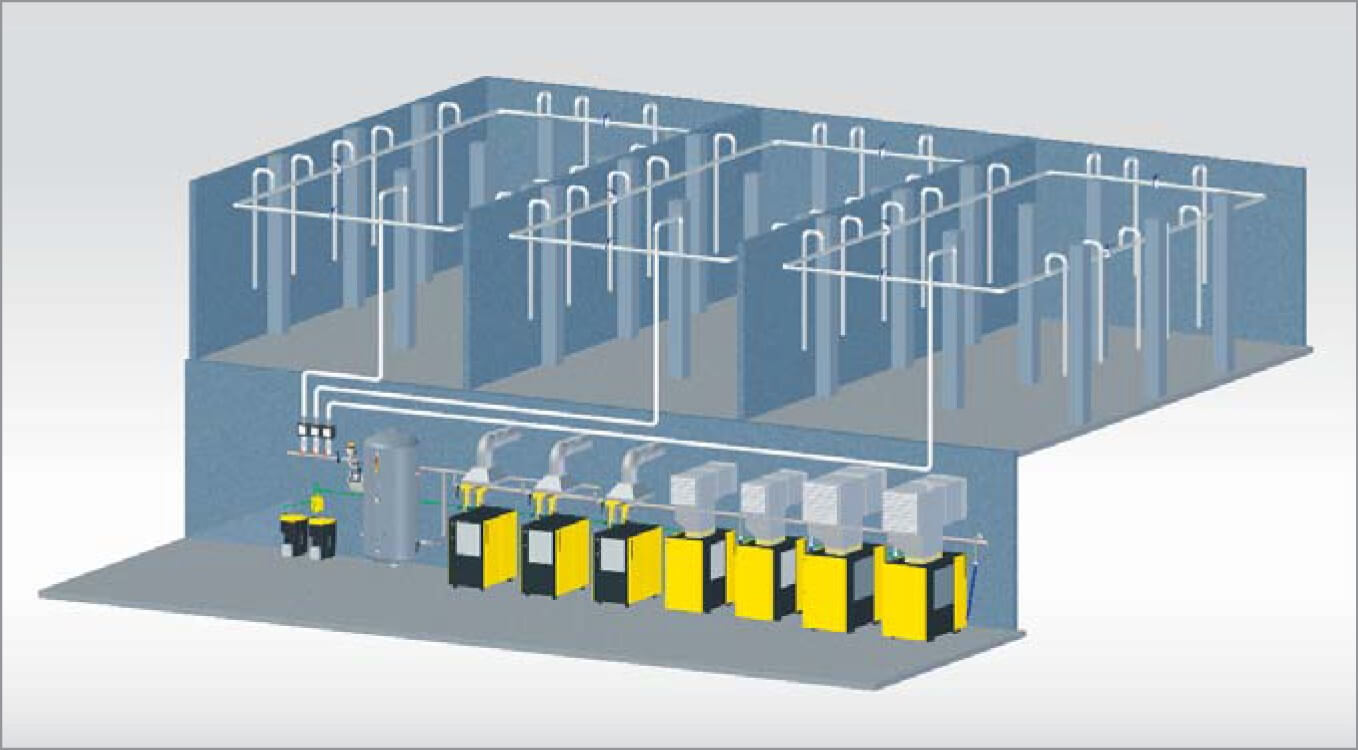

A distribution network is perfect for companies with large facilities. The design is very similar to a ring main, but includes additional longitudinal and cross connections that transform the system into a true pipe network (fig. 3).

Of course, this is the most complicated system to install, but any additional effort is more than rewarded through the advantages that it brings. The network structure provides a reliable and energy-efficient supply of compressed air to large production halls with no need for excessively large pipe dimensions.

On the contrary: pipe dimensions can be kept to a similar size as those in a ring main system installed in a small or medium sized business. The system has the further advantage that individual sections can be shut-down as required.

Designing the air-main

The function of a compressed air system’s air-main is to connect the separate air distribution lines for various operational facilities (buildings) with the compressed air installation (generation).

The dimensions and capacity of an air-main are dictated by the total air delivery of the compressors within the compressed air system. Care should also be taken to ensure that the pressure drop does not exceed 0.03 bar.

Air from a single compressor package

If a single compressed air package supplies air to several operational facilities (e.g. production halls), then the feed lines, and therefore the air-mains for the individual areas, should be able to deliver the maximum volume of compressed air required by that area. Once again, the pressure drop should not exceed 0.03 bar.

Pipelines bundled together in a collector within the compressed air station provide the advantage of being able to easily shut off entire work areas as required. Furthermore, with the addition of flow rate measuring equipment, the air consumption of individual areas can be easily determined (fig. 4).

Air from multiple compressor packages

If several compressor packages supply the compressed air for a large air-main system, then the piping must have sufficient capacity to be able to deliver the maximum air volume from the largest compressor package of each production area.

Again, the pressure drop between the individual packages should not exceed 0.03 bar, otherwise installation of complicated and expensive regulating systems becomes necessary (fig. 5).