The installation location and the environmental surroundings of a compressed air system greatly influence compressed air production efficiency and reliability. Here are three rules worth remembering...

1. Keep the compressed air installation clean

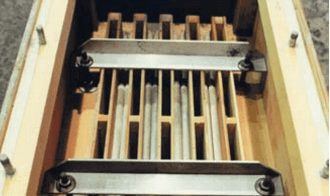

The level of cleanliness for many compressed air systems leaves a lot to be desired, even if it doesn’t look like the one shown in fig. 1. Above all, cleanliness means protecting the equipment from exposure to dust.

If care is not taken, the compressor intake filters will quickly clog up, which not only increases maintenance requirement and reduces performance, but also adversely affects air cooling.

Subsequent consequences may include costly downtime due to overheating, decreased dryer power and, as a result, condensate accumulation. This in turn can cause serious damage to air-using equipment and can negatively impact product quality.

Therefore, if dust exposure cannot be avoided by finding a dust-free installation location, then a bag filter should be used to clean the intake air (fig. 2a, 2b).

2. Ensure moderate temperatures

Firstly, the compressed air system should not be exposed to sub-zero temperatures, as this leads to production and transport of moist compressed air before it reaches the air-using equipment; in the event of frost, the condensate in the lines would freeze, resulting in operational disruptions.

Secondly, the lubrication performance of the oils and bearing lubricants used in compressed air systems is significantly reduced at temperatures below + 5 °C.

Needless to say, this can also lead to system failures. During the summer months however, as 100 % of the electrical energy used to power the compressor is converted into heat, it is important to ensure – as far as possible – that the compressor room does not exceed the outside ambient temperature. Otherwise, motors and electrical components are liable to overheat and the dryer may become overloaded due to insufficient re-cooling..

Once again, this leads to condensate accumulation and degraded performance of air-consuming equipment. In a worst case scenario, insufficient ventilation can result in a build up of heat, which causes all compressor / dryer equipment to shut-down and the compressed air supply system to completely fail.

All of these problems can be avoided simply by maintaining a moderate temperature in the compressor room. This can be guaranteed year-round via cooling systems, which automatically regulate the heat balance in the compressor station via thermostatically controlled ventilation (fig. 3).

3. Maintenance-friendly station

Although modern compressors and treatment components require significantly less maintenance than older equipment, they are not completely maintenance-free. Therefore, the systems must be installed in such a way as to ensure easy, reliable access to all servicerelevant areas.

Optimum compressed air system reliability and performance can be achieved only if all three of these points are closely observed.