The quality and efficiency of technical work depends greatly on the tools and machinery used. To fulfil their wide range of applications, PREMIUM series products meet the very highest standards in quality, reliability and versatility.

Reciprocating compressors - PREMIUM series

KAESER Reciprocating compressors PREMIUM series – a model to suit every need

Carefully constructed using the very best materials, each unit ensures a long, efficient and reliable service life. Proven quality, robust design and long maintenance intervals (fluid change required only every two years) make PREMIUM series compressors from KAESER the ideal choice for everyday use.

Symbols of quality and cutting-edge technology

Made in Germany – KAESER PREMIUM workshop compressors provide exceptional quality and performance. The LwA and CE symbols guarantee that all compressors conform to legal requirements. All PREMIUM compressors are type approved.

PREMIUM workshop compressors – Professional quality and performance

Each PREMIUM series compressor features KAESER’s low maintenance compressor block, a directly coupled electric motor and an internally coated air receiver.

For powers up to 1.5 kW the newly developed KAESER COMPACT compressor is used in which the motor and compressor casing form a single component. The compressor blocks are manufactured, assembled and tested on-site in the KAESER reciprocating compressor production facility, located at the Coburg production plant in Germany.

The high quality air receivers and electric motors are produced exclusively for KAESER KOMPRESSOREN by leading German manufacturers.

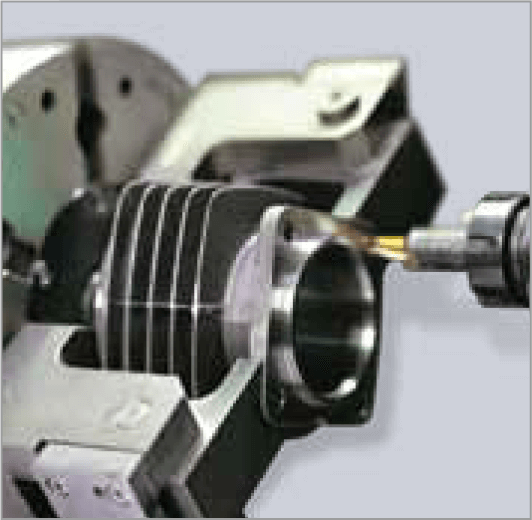

Precision machining

Using the most advanced manufacturing processes and with almost a century of experience in precision engineering, KAESER’s skill and expertise guarantees products of the very highest quality standards.

Meticulous assembly

The care that is taken in the production of a compressor block is also taken at every stage of compressor assembly.

KAESER-quality compressor block

Made from premium grade materials and subjected to rigorous inspection, every compressor block component is meticulously machined and expertly assembled.

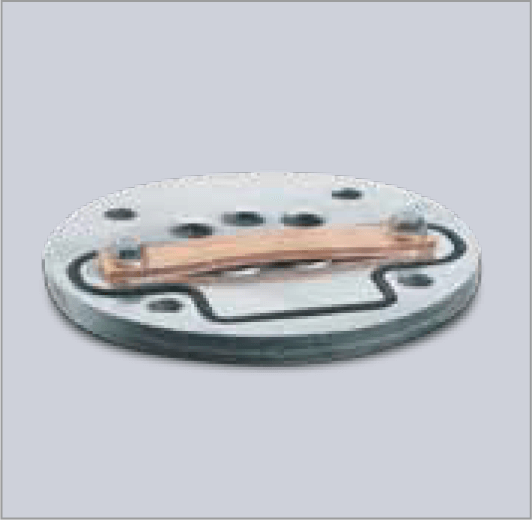

Stainless steel valves

The valve reeds in the corrosion resistant stainless steel valves are fitted with heat dissipating lift limiters to ensure air-tight valve closure and extended service life.

High-grade lubricating fluid

Fiecare compresor Kaeser pentru atelier este umplut cu fluid special, rezistent la temperaturi ridicate, care elimină aproape complet depunerile de carbon de pe supape. În plus, fluidul permite dublarea duratei unui schimb la aproximativ 1000 ore de funcționare.

PREMIUM CAR - At home on any construction site

KAESER PREMIUM CAR compressors are perfectly equipped to meet the needs of a wide range of construction site applications. All units are easy to transport and are manufactured to the highest quality standards to ensure a long, efficient and reliable service life.

A robust cover plate and solid frame protect the PREMIUM CAR against the toughest of operating conditions.

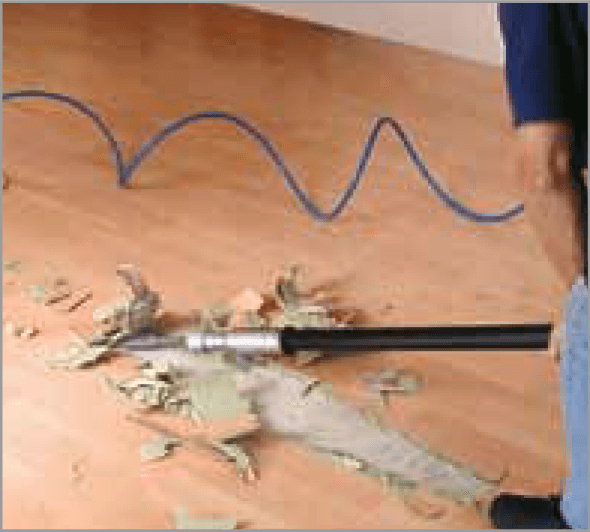

Effortless removal of plaster and tiles

Sand blasting – fast and effective

Straightforward, precise lath nailing

Compact design for excellent portability

PREMIUM COMPACT - For light construction work

PREMIUM SILENT 130/10 W to PREMIUM COMPACT 450/30 W. The compact design of these units makes them ideal for light construction work.

Modelele de reciprocating compressors PREMIUM COMPACT models are especially suited to subcontractors on small building sites, as often only one tradesman is at work at any given time. The special design of PREMIUM COMPACT trades compressors enables easy single-handed manoeuvrability.

PREMIUM COMPACT compressors are ideal for applications such as stripping floor coverings, interior work and maintenance tasks.

Easy, fast tacking of panels and profiled wood

Floor coverings stripped with ease

Clean, professional filling

Excellent portability on any construction site

Reciprocating compressors PREMIUM series - For the workshop

Compresoarele Premium pentru ateliere sunt deosebit de flexibile și de aceea sunt perfect adaptate pentru a fi utilizate în domeniul reparațiilor auto. Fie că este vorba de carrying out rapid tyre changes, repairing minor bodywork damage or sup- plying compressed air to small workshops,a PREMIUM compressor from KAESER is the perfect choice.

Impact wrenching for repair work

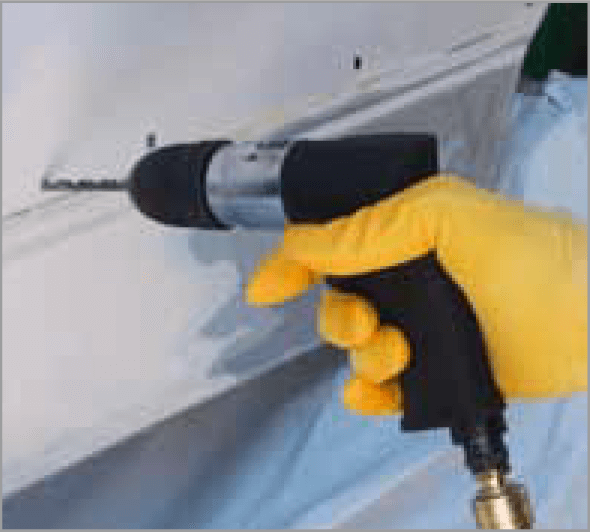

Drilling – in wood, metal or concrete

Fast and effortless sanding

Outstanding painting results with no fuss

PREMIUM – Quality at a glance

The exceptional quality of KAESER`s products is achieved by using the very best materials and components. These come together in our extensive range of PREMIUM workshop compressed air equipment that is renowned throughout the world for its durability and performance. The key compressor components are highlighted below:

- Silenced air intake filter

- Compressor block

- Maintenance-free 1:1 direct drive

- Pressure switch with unloaded start

- Filter pressure regulator with quick-release coupling

- Pressure relief valve

- Check valve

- Oil filler with vent

- Oil drain plug

- Sound & vibration dampers

- Fan / flywheel

- Terminal box with overload protection

- Condenser

- Internally-coated air receiver

- Manual cold-start option

- Rugged wheels

- Ribbed cooling pipes