With the world-renowned SIGMA PROFILE®. Flow rate 0.26 to 0.80 m³/min, Pressure 5.5 to 15 bar.

he compact all-in-one solution

SXC – integrated compressed air packages with minimal space requirement: The SXC range of turnkey rotary screw compressors from Kaeser Kompressoren combines exceptional efficiency and cost-effective performance with super-quiet compressed air production, treatment and storage of compressed air.

The SXC’s double-walled roto-moulded polyethylene enclosure conceals a complete compressed air supply system.

The perfect choice for workshops and smaller production facilities, these advanced compressor systems provide outstanding ease of maintenance and durability to ensure years of dependable service.

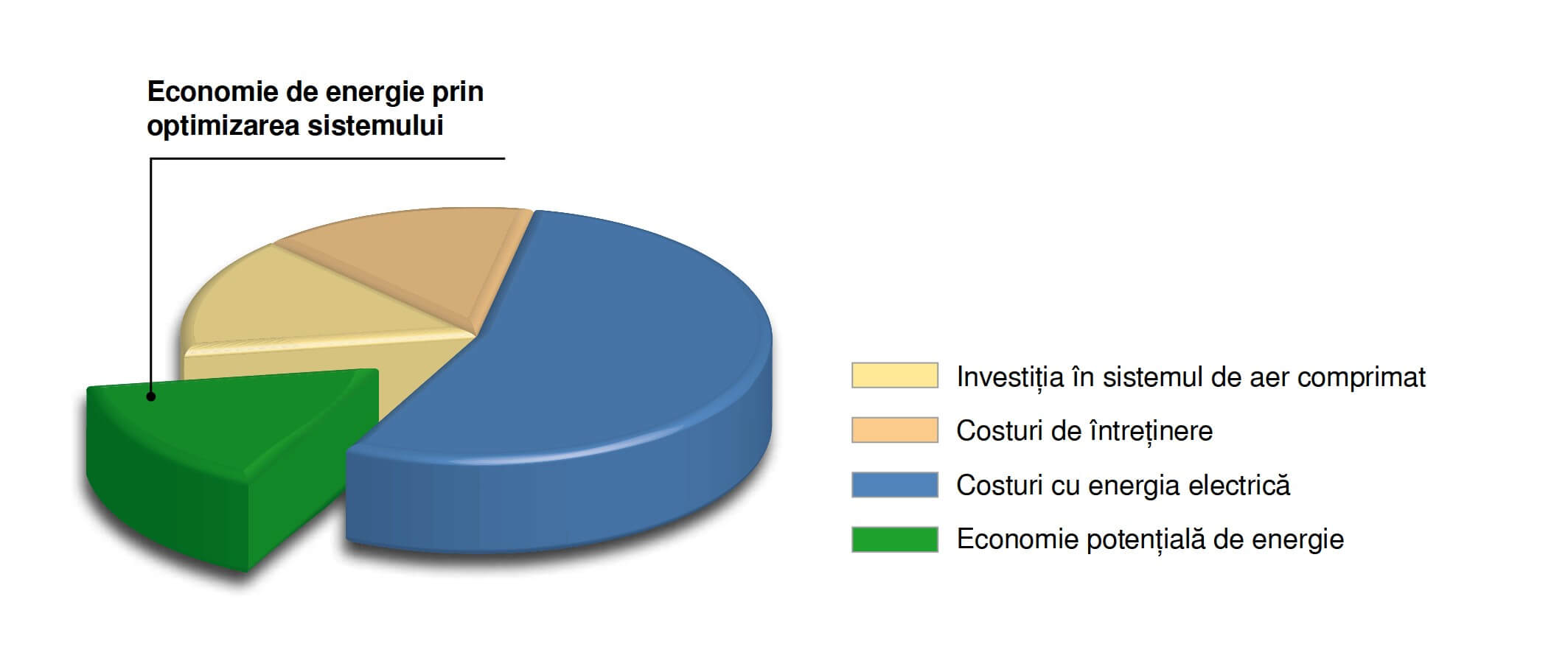

Efficiency as standard

Every SXC compact compressed air package features a rotary screw compressor fitted with a high-efficiency SIGMA PROFILE rotor compressor block that delivers more air and more savings.

Maximum efficiency and availability

SXC "all-in-one" systems feature an advanced SIGMA CONTROL 2 compressor controller to ensure reliable and efficient operation with maximum availability.

Versatile and compact

With available drive power from 2.2 to 5.5 kW, you will always find the right model to meet your specific compressed air needs. Belying their impressive performance, the four SXC models measure only 61.5 cm wide and have a compact footprint of only 0.62 square metres.

Clean and quiet

With a maximum sound level of 69 dB(A), SXC integrated packages are exceptionally quiet. Equipped with an integrated refrigeration dryer , they deliver dry, clean compressed air at all times. The electronic level-controlled condensate drain reliably removes condensate from the air receiver and refrigeration dryer without energy loss.

KAESER quality in every detail

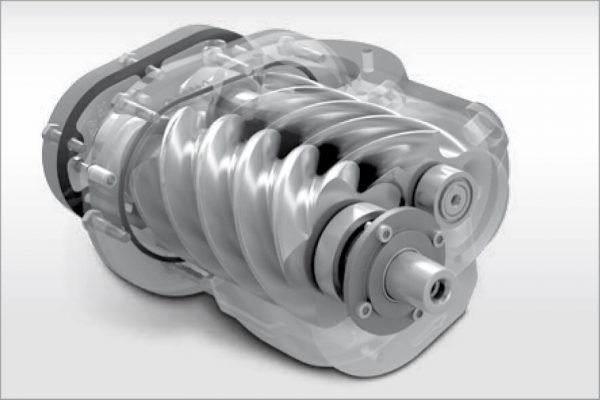

SIGMA PROFILE rotors

Every KAESER rotary screw airend uses SIGMA PROFILE rotors, specially developed by KAESER, that require approximately 10-20 % less energy than conventional rotors with the same air delivery capacity. This contributes significantly to the impressive overall efficiency of these versatile systems.

SIGMA CONTROL 2: Optimum efficiency

With its efficient start-stop control, the 'SIGMA CONTROL 2' ensures optimised compressed air system performance at all times and the easy-to-read display enables effective communication. Moreover, this advanced controller constantly monitors the entire SXC package.

Maintenance-friendly

All maintenance and service points are easily accessible once the SXC’s roto-moulded polyethylene enclosure is effortlessly lifted away. The electronic condensate drain can be inspected via a grille. Needless to say, the SXC is designed for maximum ease of maintenance.

Efficient cooling

KAESER compressors are renowned for their innovative cooling systems and SXC packages are no exception: three fans are installed to ensure optimum cooling. A dedicated fan with an independent drive motor ensures dependable fluid cooling.

Available equipment

Complete system

Ready for operation, fully automatic, super-silenced, vibration damped, double-walled, roto-moulded polyethylene enclosure.

Sound insulation

Soundproof enclosure, anti-vibration mounts, double vibration damped.

Compressor block

Genuine KAESER single-stage rotary screw airend with SIGMA PROFILE rotors and cooling-fluid injection for optimised rotor cooling.

Electric motor

Quality, German-made, high efficiency (IE3) electric motor to IP54 , Iso F for additional reserve.

V-belt drive

Maintenance-free, elasticised V-belt. No adjustment necessary.

Cooling fluid and air flow

Honeycombed dry-air filter, check valve at inlet, pneumatic vent valve, cooling fluid reservoir with dedicated separator cartridge, safety valve, minimum pressure/ check valve, micro-filter in cooling fluid circuit.

Cooling

Air cooled; aluminium cooler for cooling fluid with separate fan motor, second fan on the drive motor shaft. Automatic warm-up control (active only at very low loads).

Air receiver

Internally-coated, electronically-controlled condensate drain.

SIGMA CONTROL 2

Provides efficient compressor system monitoring and control at all times.

“Traffic light” LED indicators show operational status at a glance, plain text display, 30 selectable languages, soft-touch keys with icons, fully automatic monitoring and control as standard.

Furthermore, the system can be integrated into the Sigma Network or operated via Ethernet in master-slave communication with another system in the network; clear authorisation via RFID reader, operating data memory, integrated web server.

Electrical components

Control cabinet to IP 54, automatic star-delta starter (from 3 kW); motor-overload protection; control transformer.

Refrigeration dryer

Equipped with stainless steel plate-type heat exchangers, integrated condensate separator, electronically-controlled condensate drain, insulated refrigerant circuit.

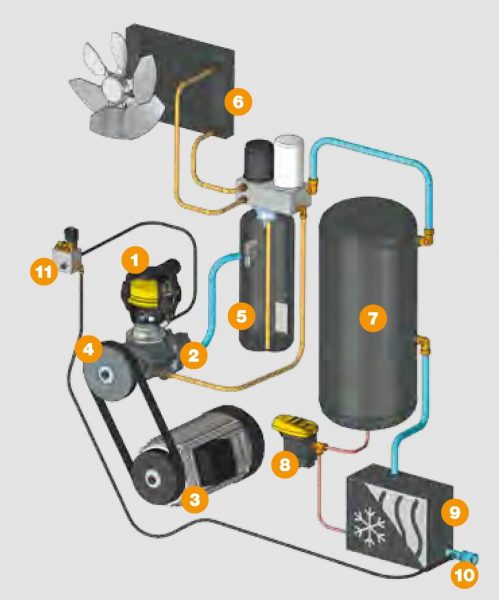

- Air filter

- Compressor block

- IE3 drive motor

- Automatic belt tensioning

- Fluid separator tank

- Cooler

- Air receiver

- ECO-DRAIN condensate drain

- Refrigeration dryer

- Compressed air outlet

- Regulating valve