Pure compressed air with lowest costs

KAESER FILTER products are key components in delivering compressed air of all purity classes in accordance with ISO 8573-1and they perform their duties with minimal pressure differential. Moreover, their service-friendly design not only ensures simple, error-free opening and closing of the filter housing, but also allows quick and clean element changes.

Filtrele KAESER FILTER sunt disponibile în patru clase de filtrare. Nouă tipodimensiuni de carcasă asigură filtrarea eficientă pentru debite între 0,60 și 14,20 m³/min.

Standard purity

The KAESER FILTER range uses modern deeppleated filter media to remove particles and aerosols. A highly effective carbon fibre mat traps oil vapours. Together with innovative through-flow, it delivers exceptional filtration efficiency with minimal pressure loss.

The impressive performance data of KAESER FILTER products have been determined in accordance with ISO 12500 and confirmed by the independent testing agency “Lloyd’s Register”.

Minimal pressure loss, maximum savings

The efficiency of a compressed air filter depends most of all on pressure loss. KAESER FILTER products are characterised by generously dimensioned housings and filter surfaces, innovative through-flow and high performance filter media. These features result in up to 50 % less pressure loss in comparison to other typically available filters.

In fact their filtration performance remains virtually constant throughout their entire service life. This reduces the burden on upstream compressors and therefore provides significant cost and CO2 savings potential.

Service-friendly design, safe handling

KAESER FILTER products feature a corrosion-resistant aluminium housing and a stable filter element. The practical bayonet lock ensures automatic positioning of the housing and element seals. Both seals are components of the filter element.

This means that a filter housing can be sealed only if a filter element has been inserted. A stop screw prevents unintentional opening of the housing when under pressure and also provides housing venting.

Low differential pressure for maximum efficiency

KAESER FILTER products are available in four efficient filter grades. All products in the range are exceptionally versatile and easily installed in combination with one another to suit the needs of the specific application.

When used with compressed air dryers and air-main charging systems from KAESER, they ensure dependable and energy-efficient compressed air treatment where it‘s needed, when it‘s needed.

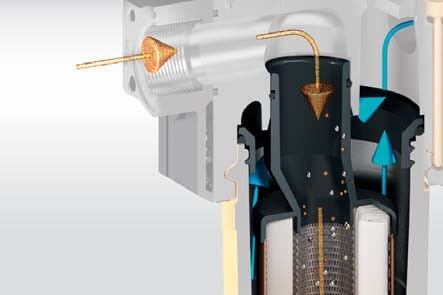

Large flow cross-section

KAESER FILTER equipment uses filter elements with specially flow-optimised element heads. The filter inlet is offset towards the air inlet, which in turn increases the flow cross-section at the air discharge side and further contributes to outstanding filter efficiency with minimal pressure loss.

Minimised pressure losses

Generously-dimensioned connection flanges on KAESER FILTER products help keep pressure losses to an absolute minimum. Since KAESER FILTER products are available with air connection flanges of various sizes, there is no need for reducer sections when connecting to different air distribution networks.

Low flow resistance

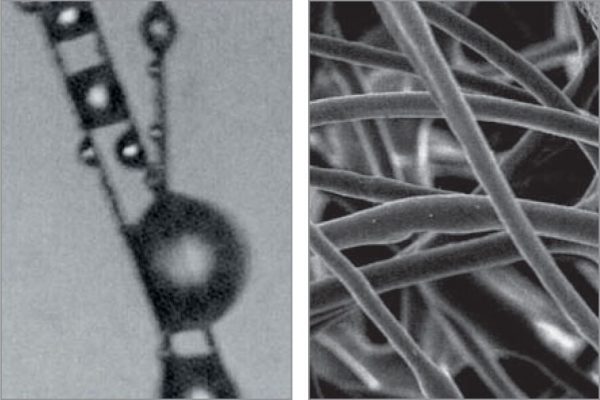

The advanced polyester material of the filter drainage layer ensures rapid and efficient oil drainage (left). Moreover, to achieve optimum filtration and contaminant retention with minimal pressure loss, KAESER particulate and coalescence filters feature high void volume filter media (right).

Consistent efficiency

Fitted as standard to KAESER particle and coalescence filters, the differential pressure gauge enables users to check filter efficiency at a glance. Furthermore, the contaminant and clean air side are reliably isolated from one another.

Standards-compliant purity in every quality class

Optimum flow distribution

The element head of KAESER FILTER units is optimised for best possible through-flow. Its internal contour structure directs the compressed air centrically into the interior of the element in order to ensure even charging of the filter media. The result: high filtration efficiency with minimal pressure loss.

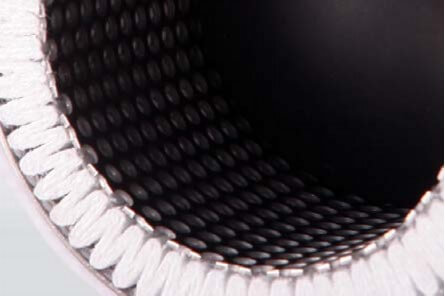

Deep-pleated filter elements

The deep-pleated KAESER dust and coalescence filter elements feature exceptionally large filter surfaces. Through their resultant increased efficiency, they therefore significantly reduce operating costs compared to conventional filter designs.

High efficiency carbon matting

Unlike the material used in conventional filters, the high efficiency carbon matting in KAESER activated carbon filters prevents channelling whilst also ensuring reduced differential pressure. Moreover, the matting provides highly effective protection against particle release.

Application-tailored combinations

KAESER FILTER units can be flexibly combined on site with optional connection kits. For example, the “Carbon Combination” consisting of a KE coalescence filter (left) and a KA activated carbon filter (right) not only retains aerosols and particulate matter, but oil vapours also.