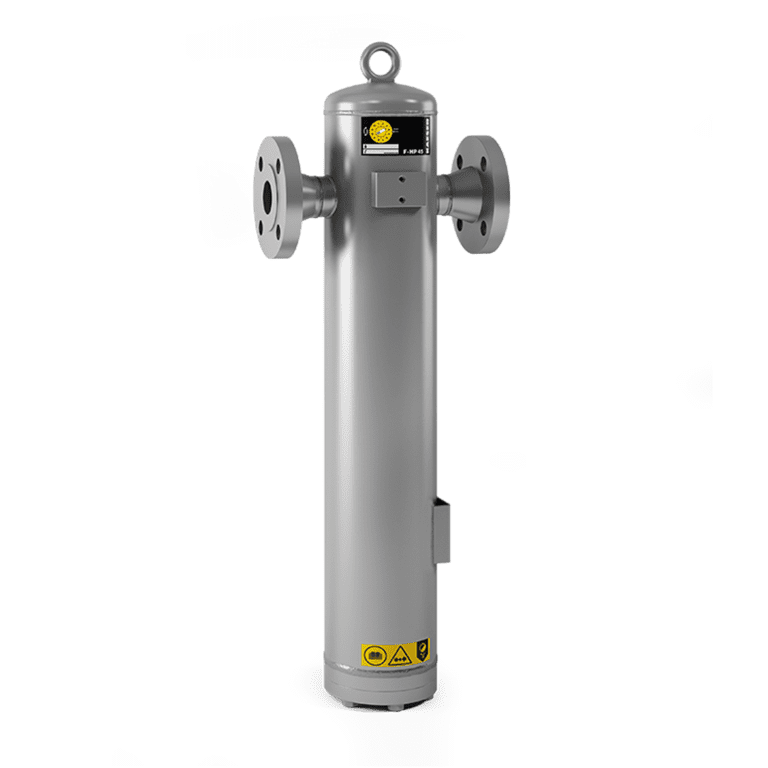

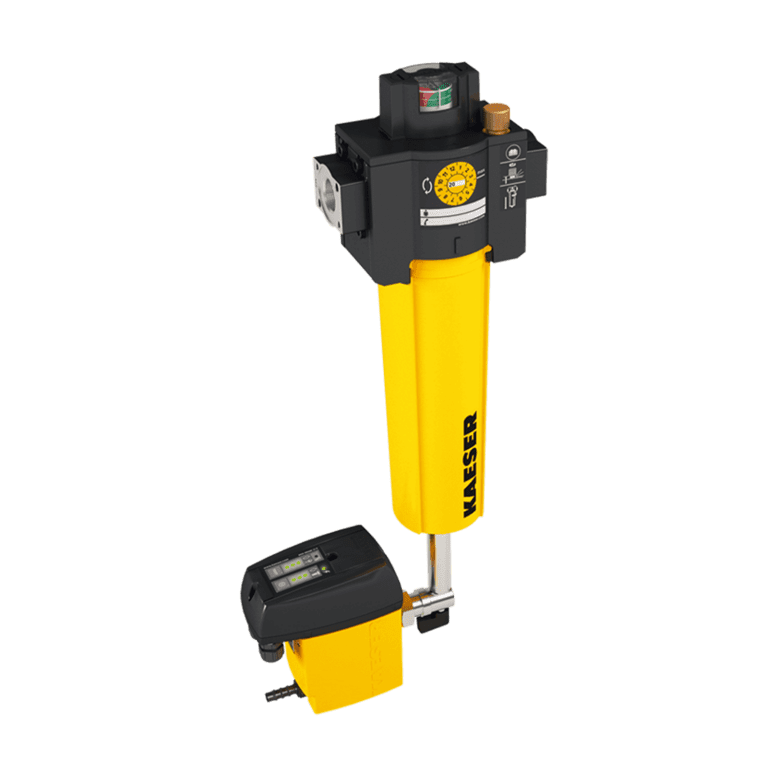

Activated carbon adsorbers

ACT series activated carbon adsorbers remove oil vapors and odors. Installed downstream of compressed air drying and prefiltration components, they reach class 1 residual oil content according to ISO 8573-1, therefore protecting sensitive production processes.

The generous amounts of high quality activated carbon filler and low pressure loss make these machines an extremely cost-effective choice: they can last up to 12,000 hours of compressor operation without replacing the activated carbon. An oil indicator mounted as standard indicates any operational disturbances.

- Residual oil content within the concentration range of 0 – 0,01 mg/m³;

- Flow rates from 1,17 – 154,5 m³/min;

- Maximum operating pressure 10 bar / 16 bar and as optional equipment 48 bar.

ACT activated carbon adsorbers must always be equipped with filtre de aer Kaeser. Installed as pre-filters and particulate filters, they ensure the maximum life of activated carbon and, with minimal pressure losses, prevent the entrainment of carbon dust in the cleaned compressed air.

Significantly lower residual oil than the limit value for class 1

Class 1 according to ISO 8573-1 is acheived with a residual oil content of 0.01 mg / m³, but Kaeser ACT adsorption dryers can provide a significantly lower residual oil content, therefore consistently complying to the limit values.

Low maintenance costs

Adsorbantele ACT adsorbers have very long replacement intervals due to their generous size and optimal airflow dynamics through activated carbon. They are also mounted in a protective steel frame.

Minimum pressure loss

Generously sized inlet and outlet diameters ensure a consistently reduced pressure difference, thus increasing cost-effectiveness.