Systematic planning is essential in order to meet your compressed air demands as efficiently as possible.

Comprehensive demand analysis, meticulous planning, implementation and expert advice all lead to significant savings in the long-run. This particularly applies to compressed air systems in industrial and workshop applications.

Reliable and efficient air system operation is achieved only through application-specific advice offered by an experienced compressed air system provider. Therefore, KAESER has developed highly effective tools for planning of new compressed air supply systems and optimised of existing ones.

With information gathered from carrying out a detailed air demand analysis (ADA) and using the specially developed KAESER Energy Saving System (KESS), KAESER’s project engineers are able to provide individually tailored compressed air system solutions.

Decades of experience in compressed air technology development and system design ensure optimum compressed air production, treatment and energy efficiency.

The results : reduced energy costs and considerable environmental benefits.

Outstanding performance with ADA and KESS

Compressed air is one of the most versatile sources of energy available for today’s production and service industries. Using ADA and KESS, Kaeser’s experts are able to plan and design a system that is specially tailored to meet all of your compressed air requirements and which will keep your air costs to an absolute minimum.

Air Demand Analysis – ADA

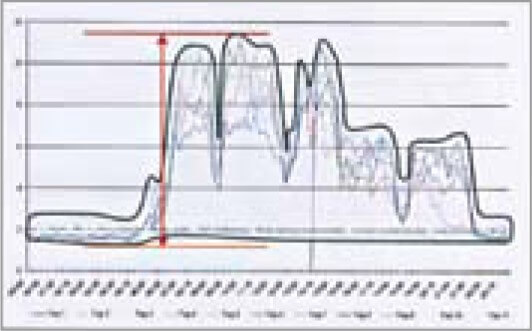

Developed by KAESER, the computer-aided “Air Demand Analysis” (ADA) allows meaningful and accurate data to be gathered to aid compressed air system optimisation. Based on the resulting air consumption profiles, KAESER's Energy Saving System (KESS) can then help determine the best system solution for the individual air application.

KAESER Energy Saving System– KESS

KESS processes the data acquired by ADA so that a state- of-the-art compressed air system can be designed and individually tailored to meet the customer's compressed air needs. An efficiency comparison between the various system options determines the most suitable system for each specific application.

A solution that meets your individual needs

With the ADA air demand profile and the KESS evaluation in mind, KAESER's engineers decide on the type and layout of the compressed air system on a case-by-case basis. Let KAESER design a compressed air system that is individually suited to meet your compressed air needs.

Reducing energy costs

Depending on utilisation, electrical power can account for up to 90 % of the total costs of compressed air production. It therefore pays to keep power consumption of compressors and peripheral equipment to an absolute minimum – many compressed air systems have an reduces electricity consumed by compressors and peripheral equipment - many compressed air systems have an energy saving potential of 30% or more.

Aici este locul în care sistemul central de comandă SIGMA AIR MANAGER SIGMA AIR MANAGER (SAM) really comes into its own, as it can control up to 16 compressors (depending on model) via a data bus link connected to each unit’s internal SIGMA CONTROL.

The SAM is able to precisely adjust on-load/ off-load operation between all of the units to achieve optimum use of energy, whilst its pressure band control allows a significant reduction in system pressure.

This leads to considerable savings, as each 1bar reduction represents a 7 % decrease in power consumption and also means less air is lost through leakage.

Systematic Cost Reduction with ADA & KESS

Once the air requirements and operating conditions have been firmly established, detailed planning can begin. All relevant parameters including required pressure level, delivery volume, air quality, system performance and energy consumption are taken into consideration when designing the new system.

Whatever your compressed air application, you can be certain that KAESER's highly experienced project engineers will deliver a system that operates with maximum efficiency and which meets all of your specific compressed air needs.

Unrivalled expertise, combined with a detailed knowledge of KAESER’s range of compressed air products, enable the KAESER experts to take advantage of every possible way to keep energy consumption costs to a minimum.

Actual air demand

The first stage when planning any compressed air system is to determine the actual air demand. KAESER experts gain a detailed insight into compressed air usage by carrying out an air demand analysis (ADA).

Determining the optimum solution

The data gathered from the ADA is analysed using the KAESER Energy Saving System (KESS). The most efficient system is then chosen from the various suggested solutions.

Checking power consumption

Exact figures show the actual power consumption of each simulated system. This information forms the basis for the next step towards determining which system is the most energy efficient.

Comparing specific power

Only when the actual power consumption is compared with the volume of air delivered can the specific power requirement be calculated. This information then provides a true picture of the various systems’ energy efficiency.

Estimarea economiei de energie

Sistemele ADA și KESS de la KAESER sunt instrumente care asigură o estimare realistă a economiilor de energie care pot fi obținute alegând sistemul de aer comprimat propus

Maximum dependability

An effective compressed air system should provide maximum availability at all times.

It goes without saying therefore, that KAESER engineers always pay particular attention to ensure that every compressed air system is planned and designed to deliver outstanding performance.

Planning with CAD

The actual installation environment can be recreated down to the smallest detail using advanced CAD technology to allow the customer to take a virtual tour of his future compressed air system long before the first compressor is even installed.

Compressed air auditing with SAM

In combination with the optional SIGMA AIR CONTROL plus visualisation software, the SIGMA AIR MANAGER is able to continuously measure and display data (load/idle, duty cycle and power consumption) from every compressor in the air system.

System pressure and air consumption data are also recorded and displayed. All information is stored for approximately 1 year and can be called up from any PC with an Internet browser, or exported for air controlling purposes.

This data can also be used by KAESER specialists to carry out detailed compressed air audits.

ADA 10

This equipment is installed on a rental basis for ten working days. The measurement procedure is the same for all compressors – including variable speed drive models.

An opto-coupler ensures trouble-free data transfer to the ADA data-logger which records compressor load/ idle information. The results are then evaluated using KAESER’s Energy Saving System (KESS).

ADA 20

Installed on a ten day rental basis, the ADA 20 records data directly from the air-main via a metering pipe through which airflow can be established by measuring the pressure differential.

The data recorded in the data-logger is then evaluated using KAESER’s Energy Saving System (KESS).

ADA 30

This system is permanently installed in the air main and also records flow volume – precise data is gathered over a wide measurement range.

The information is then passed to a microprocessor that displays the compressed air consumption value (Norm-m³) and which makes this data available on three analogue outputs (4-20mA) and an RS 232 interface.

Compressed Air Quality

Compressed air quality is classified in accordance with ISO 8573-1/2001. This regulation also covers pressure dew point and remaining oil content quality classes.

The processes and instrumentation developed by KAESER in order to carry out these measurements ensure that all systems comply with this standard and are available with a test certificate as required. All KAESER compressed air treatment products are certified.

Our technicians are also able to make individual on-site measurements of air quality at users' premises and provide expert advice on potential improvement measures.