Kaeser AQUAMAT pentru Tratarea Condensului

The condensate accumulated from the compressors usually contains traces of oil. Consequently, in most cases it is necessary to comply with official regulations which provide for compliance with a maximum oil content before condensation can be introduced into the sewer system.

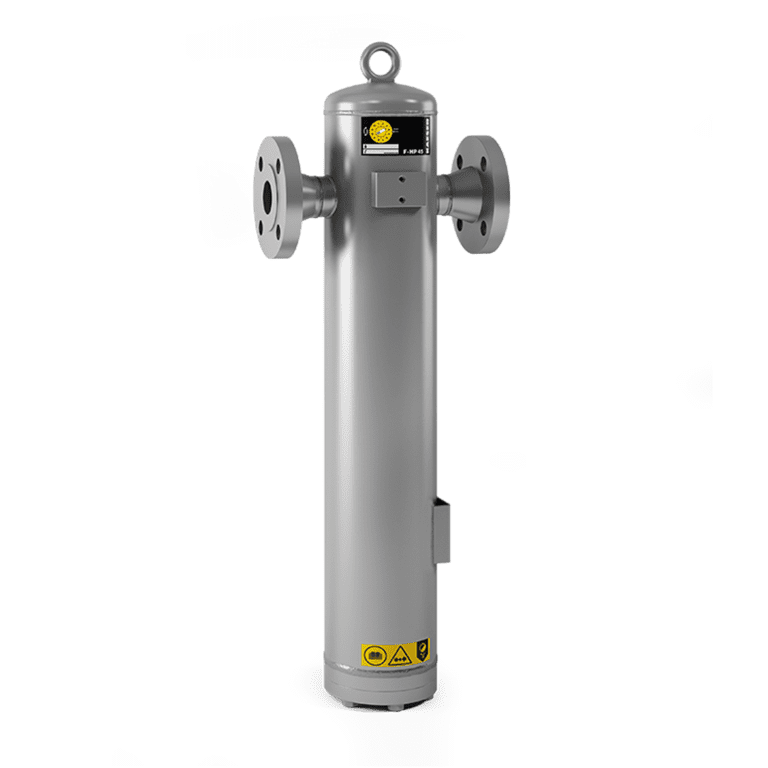

Separatorul apă-ulei-AQUAMAT îndepărtează uleiul dispersat – fiind aprobat de către Institutul German pentru Tehnica Construcțiilor (DIBt). Acestea permit tratarea condensului conform normelor juridice – direct la locul apariției and fără utilizare de energie.

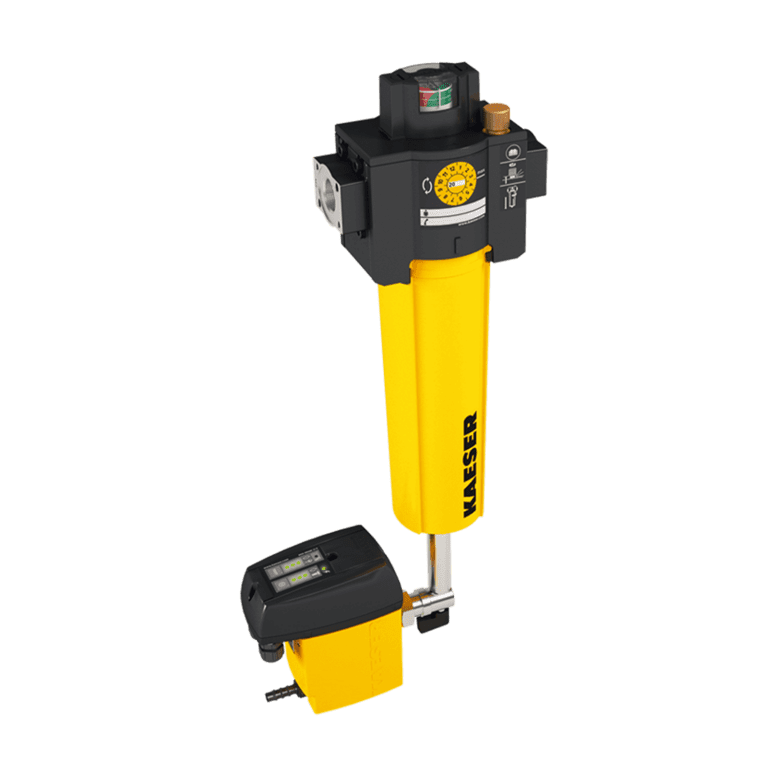

For customized installation requirements, we offer electronic level sensors, verified oil intake valves and frost protection heaters . Special condensate distributors are available for parallel coupling with multiple separators with equivalent condensate load.

Due to the savings of about 90% of the typical condensate removal costs, investments in AQUAMAT systems are rapidly depreciated, while AQUAMAT itself contributes significantly to the cost balance of the entire system in the long run - an aspect that is essential for addressing Kaeser.

Long filter life

Toate modelele CF utilizează filtre din fibre sintetice cu o capacitate sporită de filtrare (fără cărbune activ). Modelele CF9 și cele superioare au o cameră de filtre în care uleiul plutitor este tras într-un containerul de colectare extern printr-o scurgere. Acest lucru reduce sarcina pe filtru și, de asemenea, extinde intervalul de service.

Save 90% on disposal costs

The collection and treatment of condensate from compressors by specialists is expensive. In the case of AQUAMAT, only residual amounts of toxins remain for disposal - reducing typical disposal costs by approximately 90%.

Simple handling

You can visually check the quality of the purified wastewater using a solution with a reference turbidity. Models with a main filter cartridge are particularly easy to use. It can be pulled out with a handle and fixed for dripping - clean and uncomplicated.