Reciprocating compressors

- KAESER® Official Representative

- Service 24/7

- Funding from MAIB

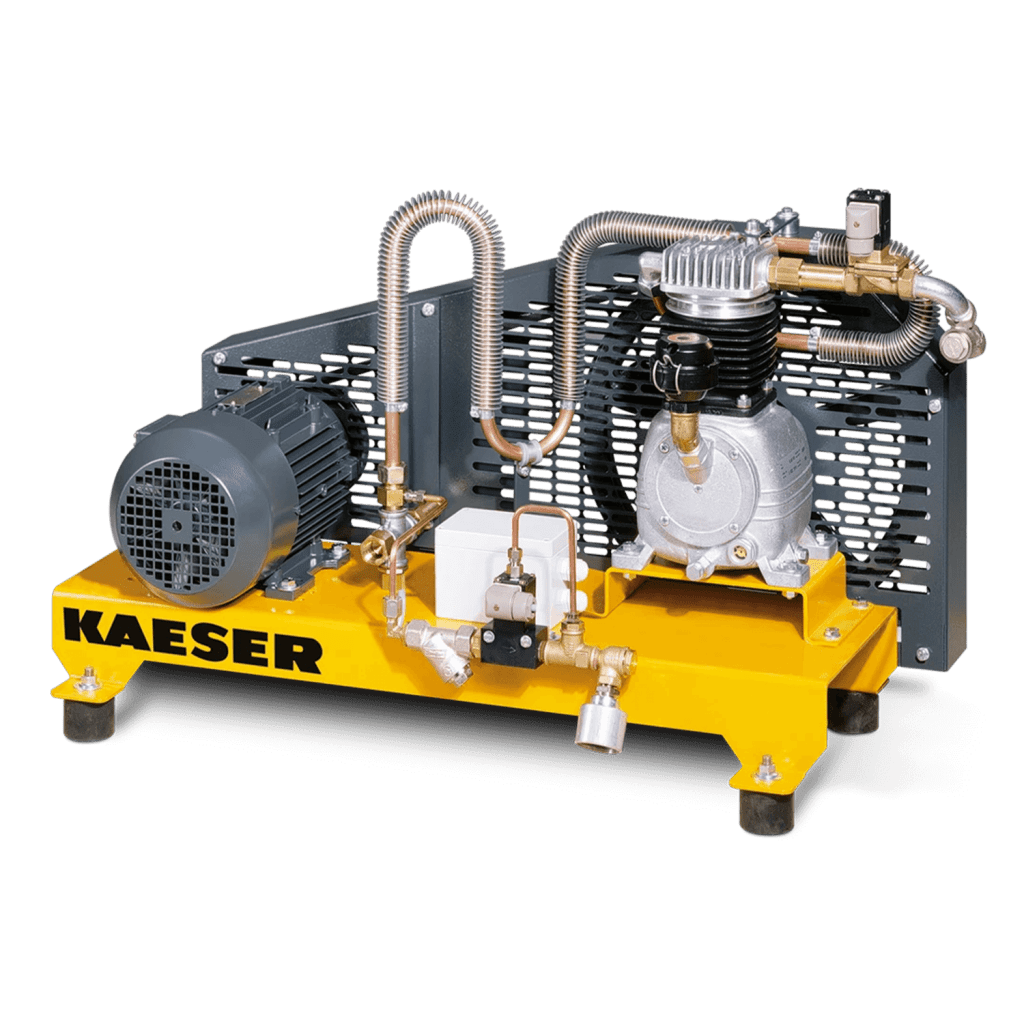

HIGH QUALITY CYLINDERS

Each Booster reciprocating compressor is equipped with very precise cylinders, each of these being manufactured through a special process, which ensures minimum oil consumption and maximum durability.

EFFICIENT ENGINES

The new generation IE3 engines are designed to consume a minimum amount of energy and provide maximum performance.

Minimum maintenance

The innovative combination of high quality components and specific design ensures long-term operation without the need for service.

- i.Comp with pressure of up to 11 bar;

- Available in PREMIUM or CLASSIC versions;

- Air suction volume between 130 and 660 l / min; from 10 to 25 bar.

STAINLESS STEEL VALVES

The valve reeds in the corrosion resistant stainless steel valves are fitted with heat dissipating lift limiters to ensure air-tight valve closure and extended service life.

RESISTANT GREASING FLUID

Each reciprocating compressor is filled with a special, high-temperature-resistant fluid that almost completely removes carbon deposits from the valves.

Precision machining

Using the latest production technologies and with over 80 years of experience in precision machining, KAESER's expertise and research guarantee products to the highest quality standards.

CORROSION RESISTANT VALVES

Compresoarele cu piston staționare au supape de tip lamelar din oțel inoxidabil și sunt prevăzute cu limitatoare de cursă care previn depunerile de carbon, asigurând etanșeitatea supapelor și o durată extinsă de viață.

HIGH EFFICIENCY COOLING

The temperature of the oil and compressed air is kept to a minimum thanks to a generous fan and cooling slats. This cooling system significantly prolongs the life of the reciprocating compressor and its associated instrument.

GERMAN COMPRESSION BLOCKS

Being made of the best materials and subjected to rigorous inspection, the compression blocks are meticulously processed and carefully assembled. The transmission losses are actually eliminated, the durable electric motor being connected directly to the compression block.

COMPLETE SYSTEMS

Ready to operate, fully automated, super quiet and vibration-free.

SILENT COMPRESSORS

Systems are lined with washable foam and double vibration damping systems.

FULLY AUTOMATED

They have an electronic system that controls the working speed, the motor overload protection and are being EMC certificated for the use as a power source for home electrical systems.

Authorized service 24/7 throughout Rep. Moldova

Maintenance and repair work is carried out exclusively by qualified specialists. We only use original Kaeser parts.

All engineers and technicians are trained in Kaeser's factories in Germany to ensure professionalism and competence at the highest level.

RECIPROCATING COMPRESSORS SUITABLE FOR VARIOUS APPLICATIONS

The optimum operating capacity of a reciprocating compressor is between 60 and 70%. For high-oscillating operation with peak load, they are the best option, especially for craft enterprises, workshops and small industry.

In the form of Booster compressors, reciprocating compressors can targetedly compress an existing network pressure up to 45 bar.